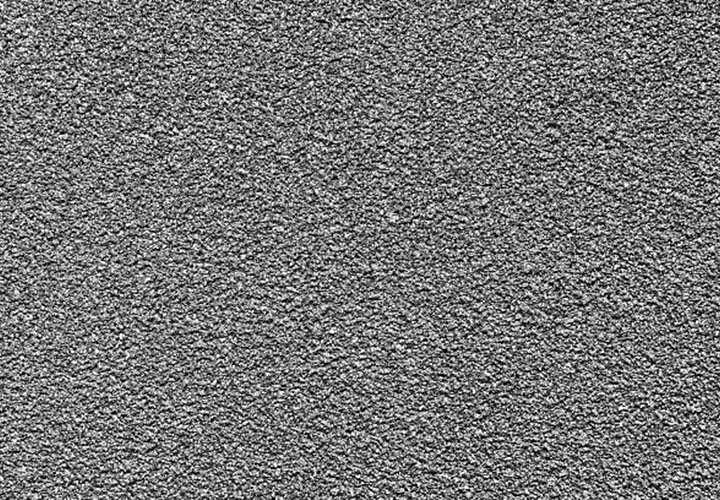

Scraped Sand

What is Scraping?

It is the impact of blasting sand on metal surface with high pressure air. During this impact, while the sand abrades the metal surface at the micron level, it also scrapes and cleans all kinds of unwanted substances on the surface.

Usage Areas of Scraped Sand

The contact of steel with oxygen, the effect of water and some acids, oxidizes over time and metals rust. Over time, it rots and becomes unusable. In order to prevent the contact of the steel with oxygen, sandblasting should be done by industrial sandblasting and blasting method. For this purpose, silica sand is used as sandblasting material in all steel materials.

"Scraping is the impact of SAND on the metal surface with high pressure air. During this impact, while the sand abrades the metal surface at the micron level, it also scrapes and cleans all kinds of unwanted substances on the surface.”

Basalt, iron grit, steel grit and steel shot products are also used in the industry for blasting, ie sandblasting. Blasting sands are used in various sizes according to the technical properties and corrosion rates of the metal. Coarse granule sandblasting products are generally preferred for high corrosion and thick materials. Fine granular products should be used for more sensitive sandblasting works and fine materials.

Sandblasting should be done as soon as possible in dry weather, and the painting process should be started. Because after the rust and unwanted formations on it are cleaned, the steel is even more vulnerable to rust. If the weather is also humid, sandblasted steel will immediately begin to tarnish and rust.

Grading of Sandblasting :

Thank you very much for this valuable comment. Our aim is to be one of the pioneers of the Turkish Sand industry, and as one of the best sand producers like you, Atak Oyun Kumu is always at your service with all kinds of Sand in the mining and industrial sector with years of accumulated experience.